The Nanotechnology and Advanced Materials Unit within the Process Transfer and Integrative Technology Transfer Centre (CTPTI) at IQS boasts several laboratories equipped for research and technology transfer activities mainly related to particle and cell characterization and the analysis and characterization of polymeric materials, biomaterials, ceramic materials, and graphene, among others.

Close-up of the RAMAN DRX2 microscope

The Nanotechnology and Advanced Materials Unit within the Process Transfer and Integrative Technology Transfer Centre (CTPTI) at IQS boasts several laboratories equipped for research and technology transfer activities mainly related to particle and cell characterization and the analysis and characterization of polymeric materials, biomaterials, ceramic materials, and graphene, among others.

The facility is home to various scientific devices and equipment to perform analysis and characterization, including the following:

Particle Characterization Equipment:

- Zetasizer Nano device (Malvern Panalytical), a particle size and molecular size analyser for light scattering in the nanometer range.

- Mastersizer 3000 device (Malvern Panalytical), enables determining the size and distribution of particles in the micrometric range by means of a laser diffraction system.

- NanoSight LM10 device (Malvern Panalytical), similar to the first one, it allows the characterization and analysis of particle distribution in the nanometric range by means of a light scattering system. It is also coupled to a microscope to establish the population of the particles under study.

SP8 high-resolution laser scanning confocal scanning microscope (Leica Systems) for cell characterization. It enables observing a wide range of fluorophores, as well as cell dynamics in detail. Due to its special characteristics, it also makes it possible to analyse materials, biomaterials, biological tissue, and cell cultures.

Empyrean X-ray diffractometer (Malvern Panalytical). This device makes it possible to analyse organic and inorganic materials, identifying and quantifying the different crystalline phases.

Regarding the pharmaceutical industry, it also enables the analysis of polymorphisms present in the active ingredients.

Raman DRX2 Microscope (Thermo Fisher). The Raman spectroscopy device facilitates the direct analysis of materials without prior preparation and in a non-destructive manner. Being coupled to a microscope allows the acquisition of images with composition maps. It makes it possible to obtain information on the chemical composition of organic and inorganic compounds in any material condition. It is a key technique for identifying drugs and carbon nanomaterials such as graphene, carbon nanotubes, fullerenes, or diamond-type compounds as these compounds do not have characteristic IR bands and the analyses can be carried out directly in aqueous solutions.

Some examples of its application include: making it possible to determine the shape and structure of polymers; analysing APIs in design and manufacturing stages; analysing tissues in different fields of medicine; identifying materials such as pigments in works of art; identifying and characterizing diamonds; and detecting unknown substances in forensic investigation.

Thermo Scientific Nicolet™ iN™10 microscope, a microscope coupled to an IR spectrometer for the analysis of a wide range of materials (polymers, rubber, paints, coatings, pharmaceuticals, cosmetics, etc.). It makes it possible to measure particles less than 50 microns in size. Its software allows making surface studies, monitoring changes in composition, or detecting the presence of impurities.

This device is essential in the study and analysis of microplastic samples, where the measurement and the amount of particles are so small that any type of manipulation can lead to deviations in the results. The possibility of performing individual IR analyses for each of the particles individually represents a qualitative leap in this field.

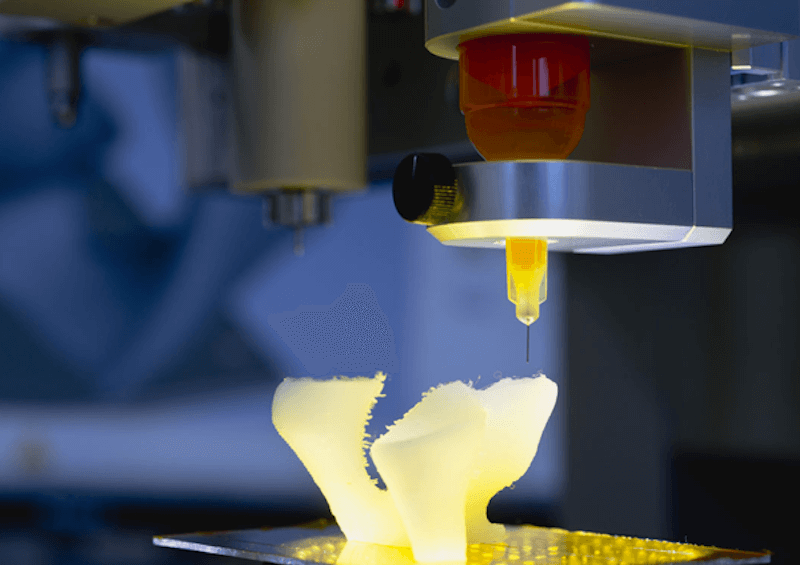

Bioimpresora REGEMAT 3D, a device that combines extrusion technology with the deposition of molten material, thus allowing the combination of different materials and printing techniques in the same application. Some examples of its application include 3D printing of anatomical silicone models to improve a surgeon's experience when planning or doing an operation or printing biomaterials of human origin for cartilage regeneration.

The acquisition of some of these devices has been possible through the File 2015 ERDF S-05 project. IQS has received co-financing from the European Regional Development Fund, granted by the Government of Catalonia's Ministry of Business and Knowledge, through the Directorate General of Research (File 2015 ERDF S-05). This grant forms part of the call for grants to select unique institutional projects to construct, acquire, equip, and/or substantially expand buildings for R&D infrastructure that make it possible to produce excellent research, attract talent, and develop knowledge transfer and valuation activities, which can be co-financed by the European Regional Development Fund (ERDF).