Dr Antonio Hinojo Ramírez recently defended his doctoral thesis at IQS, in which he developed new ceramic electrochemical hydrogen sensors using a solid electrolyte with high proton conductivity, thermal stability, and resistance to reducing atmospheres.

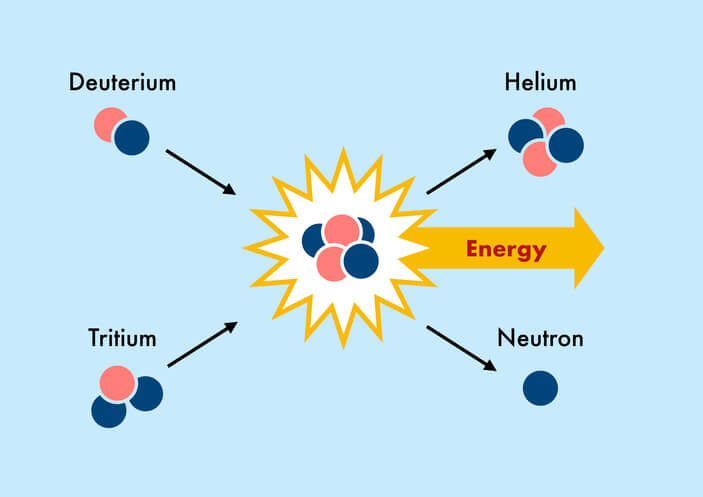

Nuclear fusion represents a promising and sustainable solution to growing global energy demand as an alternative to the use of fossil fuels and renewable energy. It entails a process that seeks to reproduce the Sun’s energy production system on Earth, which also requires addressing numerous technological challenges to implement it.

In the Electrochemistry and Bioanalysis Group (EQBA) at IQS, researchers from the Electrochemistry Laboratory are working on various projects related to nuclear fusion technologies. Future fusion reactors will use deuterium and tritium as fuel: while deuterium is easy to obtain from natural sources such as water, tritium will be generated in the fusion reactor itself, in Tritium Breeding Blankets (TBB). In these systems, analytical tools will be needed to determine the isotopes.

Electrochemical sensors based on solid electrolytes are a promising solution to carry out these measurements thanks to their ability to operate in the demanding conditions of the reactors.

Within this context, and following prior research initiated by Dr Eduard Juhera and Dr Marc Nel·lo in the field of electrochemical sensors for fusion reactions, Dr Antonio Hinojo Ramírez recently defended his doctoral thesis at IQS under the title BaCe0.6Z0.3Y0.1O3-δ ceramic elements for electrochemical hydrogen sensors: methods for the modelling, characterization, and evaluation of prototypes. The thesis was conducted at the IQS Electrochemistry Laboratory, under the supervision of Dr Sergi Colominas Fuster and Dr Jordi Abellà Iglesias, with the main objective of developing electrochemical hydrogen sensors using BaCe0.6Zr0.3Y0.1O3-δ, a solid electrolyte with high proton conductivity, thermal stability, and resistance in reducing atmospheres.

New Ceramic Electrochemical Sensor Prototypes

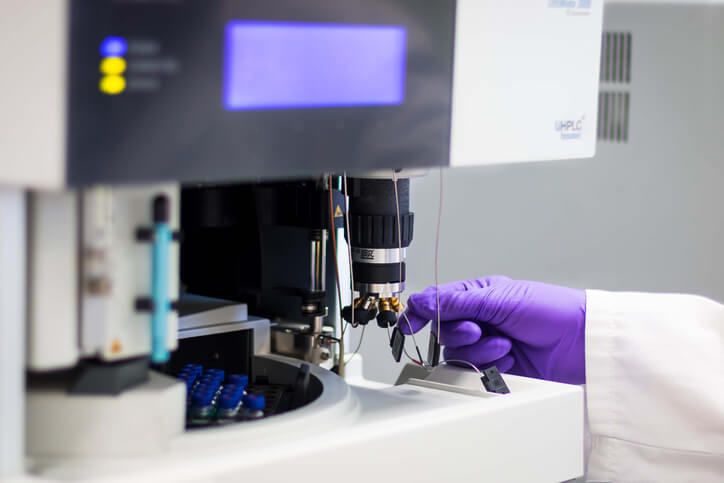

To achieve this objective, Dr Hinojo first manufactured BaCe0.6Z0.3Y0.1O3-δ ceramic elements using different shaping techniques such as cold isostatic pressure, 3D printing by extrusion, and 3D printing by lithography in order to achieve the desired geometry in the sensor.

The shaped ceramic elements were characterized in terms of crystal structure, microstructure, and proton conductivity, the latter using electronic impedance spectroscopy (EIS), which confirmed that the electrolytes obtained were suitable for use in sensors.

Finally, the sensors developed by Dr Hinojo were evaluated as hydrogen measurement elements in the gas phase between 400 °C and 600 °C, in potentiometric and amperometric modes. Parameters such as sensitivity, linear range, response and recovery time, accuracy, and precision were analysed. Sensors based on 3D printing, through extrusion and lithography, stood out for their balanced performance and sensitivity, respectively.

The results obtained in the research conducted in this thesis position ceramic electrochemical sensors as very promising tools for use in nuclear fusion reactors, enabling manufacturing using 3D printing technologies as an option to produce them industrially.

Related publications

Antonio Hinojo et al, Optimization of 3D printing conditions for BaCe0.6Zr0.3Y0.1O3-δ in the construction of amperometric high-temperature H2 sensors, Talanta Open, 11, 2025, 100454.

Antonio Hinojo et al, Development and characterization of electrochemical hydrogen sensors using different fabrication techniques, Fusion and Engineering Design, 204, 2024, 114483

Antonio Hinojo et al, Shaping techniques’ influence on the electrochemical properties of BaCe0.6Zr0.3Y0.1O3-δ proton conductor, Ceramics International, 50, Issue 20, partC, 2024, 40249-40260

Antonio Hinojo et al, A novel solution for hydrogen monitoring in fusion processes: 3D printed BaCe0.6Zr0.3Y0.1O3-α sensors, Nuclear Materials and Energy, 39, 2024, 101661

Antonio Hinojo et al, BaCe0.6Zr0.3Y0.1O3-α electrochemical hydrogen sensor for fusion applications, Fusion Engineering and Design, 188, 2023, 113452

This thesis has received support from the Semolmetfus (RTI208-095045-B-I00) and Ecsenfus (PID2022-143047OB-I00) projects under the Ministry of Science and Innovation/State Research Agency.