Within the Industries of the Future community, IQS has participated in the PLASTFUN project where advanced surface functionalities and their large-scale production have been defined, and now has a validated simulation tool for optimising parameters under industrial conditions.

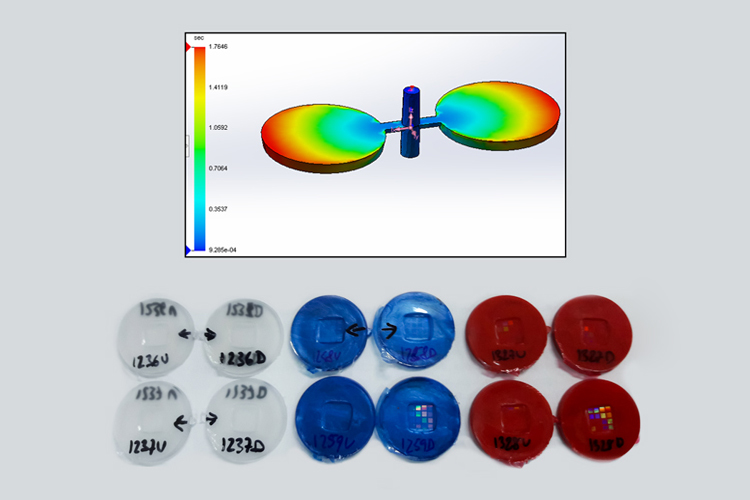

Injected parts to find replication parameters for nanometric colours and a virtual simulation model.

Within the RIS3CAT Future Industries Community, supported by the Government of Catalonia, researchers from the Industrial Engineering, Chemical Engineering, and Materials Science Departments in the IQS School of Engineering have participated in PLASTFUN, a project co-financed by the European Regional Development Fund (ERDF).

The main objective of this project was to establish the techniques and methods necessary to apply printed electronic circuits and nano-textures in injected plastic parts. The project also aimed to coordinate the necessary resources to establish a pilot line to manufacture plastic parts with functionalized surfaces, which would allow local companies to develop products with these technologies and obtain the knowledge needed to make producing them profitable.

Validated simulation tool for industrial processes

Through their experience in the field of simulation, IQS researchers led by Dr Andrés García in the Industrial Engineering Department and Dr José J. Molins in the Chemical Engineering and Materials Science Departments have participated in the simulation and reproduction of nano structures in the plastic injection process. The company Flubetech (an IQS spinoff in its early days), led by IQS's own Dr Carles Colominas, has also been part of the project, contributing its experience in coating moulds to prepare surfaces.

For IQS, the main objective was to develop a simulation tool validated through industrial production experiments and to optimise the injection parameters considering the cycle time for actual parts. Specifically, the project was able to develop this tool by lowering the simulation time from 72 hours to 10 minutes and could define the injection temperature, the mould temperature, and the injection cycle time in order to copy the nano-metric pattern that gives a surface its properties and characteristics.

Informational video https://youtu.be/4c9W86a224M

Other IQS contributions

IQS researchers have played various roles within the project, such as defining demonstrators and the requirements for their manufacturing processes, evaluating limits and technological possibilities, and defining the geometry of the parts and the manometric patterns to be later replicated by simulation.

In working on developing texturing solutions, IQS conducted the simulation of nano-texturing in plastic injection by studying laboratory test tubes to learn how to inject to copy nanometric patterns and have surface functionality.

In terms of configuring the pilot infrastructure, IQS studied the different parameters to uncover which ones can be simulated in large-scale production.

Finally, in the final phase of industrial scaling, the IQS groups carried out large-scale texturing studies of micro and nano-texturized films, as well as studies on the injection of parts with large-scale moulds and nano-texturing simulations, also with large-scale production parameters.

In short, IQS has been able to participate in a consortium where the functions intended to be brought to large-scale manufacturing have been defined, and the texture has been manufactured on the coated moulds that have been injected to try to replicate these surfaces by incorporating films and concrete conductive inks. The challenges of bringing nano-functional surfaces to large-scale production were also analysed within the project.

IQS now boasts a simulation tool that has been experimentally validated in industrial conditions, with a response time suitable for industry's needs.