Dr Rafael González Olmos and Dr Javier Fernández García, members of the IQS Environmental Processes Engineering and Simulation Group (GESPA), and the company GASN2 are working together on the CAPTAPUR project, with the aim of designing and implementing a prototype high-purity CO2 capture plant using adsorption processes. This project is funded within the Producte call, which is awarded by AGAUR, the Agency for University and Research Grants and Knowledge Industry grants. The purpose of the Producte call for proposals is to finance projects aimed at obtaining prototypes to assess and transfer the results of their research.

Since 2014, IQS and GASN2 have been working on the development of new CO2 capture processes with adsorption, which make it possible to address the problems associated with the consolidated commercial amine capture technology: high energy consumption in the regeneration of amines and issues of corrosion, toxicity, and degradation of amines along with the high cost of the system. It entails an excessively expensive technology for small and medium-sized companies, which is why GASN2 and IQS have developed a new CO2 capture technology based on Vacuum Pressure Swing Adsorption (VPSA), which improves upon all of these issues and is especially aimed at small and medium-sized companies. The VPSA technology has been validated and patented and a prototype was built that allowed a proof of concept (TRL3) with the capacity to produce 70% CO2 from combustion gases.

As a result of this collaboration, a first industrial doctorate (Dr Ángel Gutiérrez Ortega) was carried out to establish the foundations of the technology derived from IQS and GASN2 knowledge, and there is currently a second industrial doctorate in progress (María García Atencia) to enhance the TRL of the technology and reach CO2 purities of 99%.

Within this collaboration, various articles related to the developed technology have been published, including:

- R. González-Olmos et al, (2023) Parameter screening of a VSPA cycle with automated breakthrough control for carbon capture, Fuel, 339, 127298.

- R. González-Olmos et al, (2022), A fast methodology to rank absorbents for CO2 capture with temperature swing adsorption, Chemical Engineering Journal, 435, 134703.

- R. González-Olmos et al, (2022), Comparative study of binderless zeolites and carbon molecular sieves as adsorbents for CO2 capture processes, Journal of CO2 utilization, 61, 102012.

Purer CO2 capture prototype with adsorption technologies

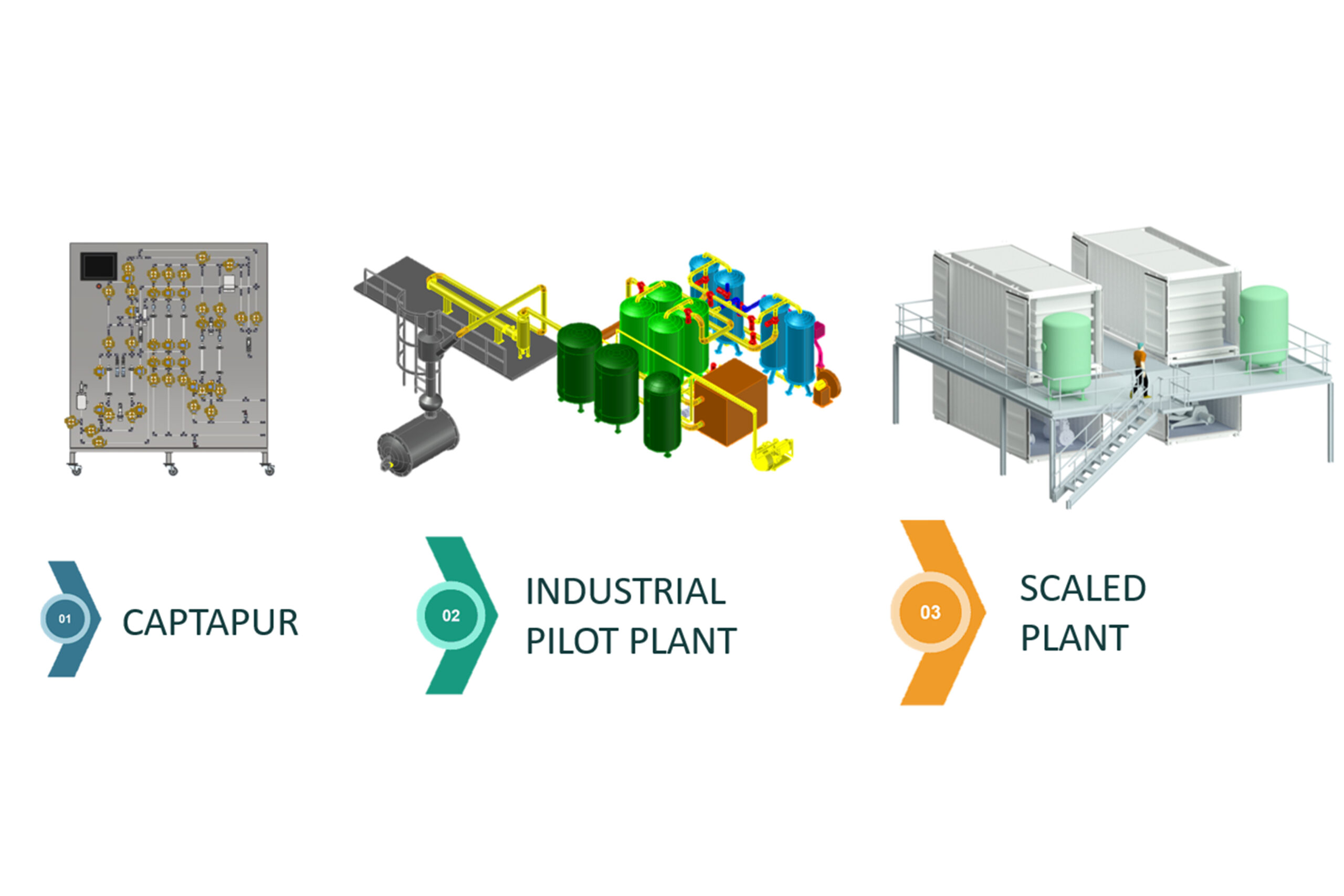

Currently, the IQS GESPA group and GASN2 are working on the CAPTAPUR project to scale the CO2 capture technology through adsorption processes to a prototype (TRL6) that will serve as the basis for designing the first operational high-purity CO2 capture plants (99%), based on adsorption processes in real industrial environments (TRL7). The designed prototype will be validated and used to make the selection of the optimal adsorbents, then used to optimize the CO2 capture operation cycles.

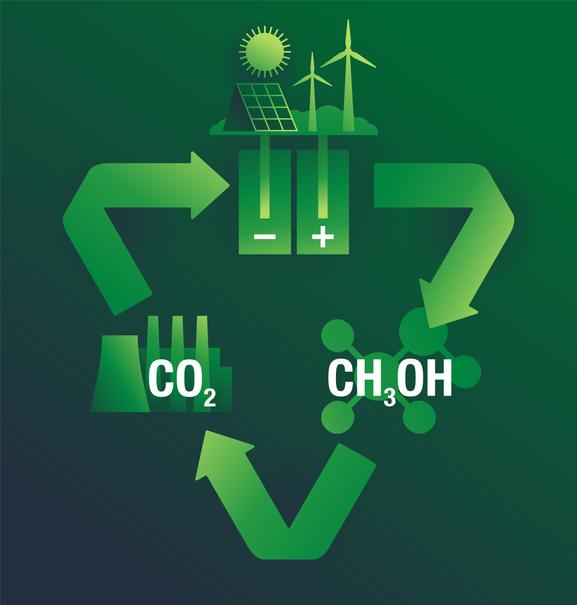

This technology will allow industries to use the CO2 they generate in their natural gas boilers, avoiding emissions in the industries themselves in the facilities that produce industrial CO2 and minimizing the transport of this CO2 from the production centres to where it is used, thus promoting an important change towards a circular economy system.

In the words of Jordi Pujol Parals, Chief R&D&i Officer at GASN2, “at GASN2 we are deeply committed to sustainability and proud to lead CO2 capture technologies adapted to industry’s current needs. Collaboration with the IQS GESPA group on this project allows us to apply and optimize the scaling of our capture technology for adsorption to high purity levels, testing it in industrial environments and optimizing process efficiency. This includes developing a modular system that is flexible and efficient, adapting to the different volumes that industry has and contributing to a circular economy model with the reuse of captured CO2. With CAPTAPUR, we are reinforcing GASN2’s leadership in sustainable capture, promoting decarbonization aligned with climate objectives and driving the sector towards a cleaner and more environmentally responsible industry.”